Due to the ever-increasing use of technological equipment in all productive activities, the harmonics phenomenon employs an increasing number of electrical applications, even sectors that until recently were not considered to be affected by it.

In this article, we present the sectors in which harmonics occur more frequently and how they are dealt with according to the specificities of each sector.

Industries

Industries are the first sector, where harmonics were an issue. With the gradually increasing use of electronic power (thyristors etc), harmonics have expanded rapidly in recent years. The complexity of the equipment, as well as its interaction with various systems, create large and varied harmonics phenomena.

The main sources of harmonics in industries are as follows:

- Power electronics (inverters, rectifiers, inverters etc)

- CNC machine tools

- Arc arc welding devices

- Electric ovens

- Pumps

In order to deal with the phenomenon of harmonics in the industry, the optimal choice is to use active filters because the filters that are required to cope with the harmonics in the industry must be characterized by both high performance and high resistance to the difficult conditions of the industrial environment.

For example, in industries experiencing a major dust problem (such as cement, grinding, quarrying, quarrying, etc.), the usual air-cooled filters do not perform well, as the cooling system bursts (or “gets wet”) with the risk of overheating the filter and be destroyed.

Active EMMIS filters have a water cooling system that guarantees complete safety and functionality even in the most burdensome industrial environments.

Shipping

Another very important sector with the widespread phenomenon of harmonics is shipping. Harmonics have appeared on different ship types due to a variety of factors per case.

For example, on board passenger ships the harmonics appear mainly due to the large air conditioning units. High-speed ships (navy, yachts) have experienced problems with propulsion and rudder systems. Finally, special-purpose vessels (fishing, underwater concrete, etc.) have more special equipment, such as lifting equipment, inverters, etc. and face other forms of harmonics.

As in the case of industrial applications, even in shipping, the handling of harmonics is done by using active filters.

This is due to the fact that harmonics of the same class (5th, 7th etc) appear in both sectors, and the THD harmonic destortion values do not differ significantly.

Hospitals

Hospitals are another area where high levels of harmonics are detected.

The sources of harmonics in hospital facilities are mainly the ever-increasing use of axial and magnetic tomography devices as well as ray generators.

In addition, due to increased safety requirements, international standards provide for hospitals stricter limits on the level of harmonics compared to other sectors.

More specifically, the IEEE 519 standard provides for hospitals a maximum Harmonic Deformation Rate (THDv) of only 3%, while for industry the corresponding maximum deformation value is 8%.

Optimal handling of the harmonics in hospital facilities requires the use of active filters, as the active ones are the only kind of filters with full harmonic damping capability. Therefore, active filters are the only kind of filters that can achieve the aforementioned percentages of harmonic distortion.

Building facilities

In terms of building facilities, harmonics appear mainly in large building complexes that include a large number of electronic equipment, a large number of luminaires and a multitude of UPS, which are equally large sources of harmonic output.

Indicatively, the most common cases of harmonic occurrence are:

- Office and corporate office buildings

- Hotels

- Banks

- Data Centers

These buildings have a large number of single-phase loads, resulting in high harmonic values in the neutral conductor. The fact that in these cases the entirety of the harmonics pass through the neutral duct can lead to its destruction, as the dimensioning of its cross section has rarely take into account the possibility of harmonic occurrence.

For such plants, special versions of active filters have been developed by connecting four (4) conductors (instead of the usual three (3) conductors) to offset the harmonics of the neutral conductor.

Renewable energy sources

Private electricity producers from large wind farms and photovoltaic parks often face problems with national grid operators because of the high harmonic values that the generated current is entering into the grid.

This is due to the fact that the old technology equipment (wind turbines, panels) produce more harmonics, which they channel to the transmission network through the transformers, which are not capable of damping harmonics.

Also, due to the sensitivity and the limited lifetime of the capacitor arrays, the reactive power is gradually increasing, which results in additional charges.

To deal with harmonics in large RES projects, combined harmonic and reactive power compensation applications are required.

EMMIS provides solutions with a large number of active filters and step-up transformers, which function properly even in medium-voltage or high-voltage grids.

Special phenomena

In addition to the above-mentioned applications, there are certain phenomena, which are due to the harmonics but can not be dealt with by the usual active filters of the market.

Such a phenomenon is flickering as presented below.

Flickering

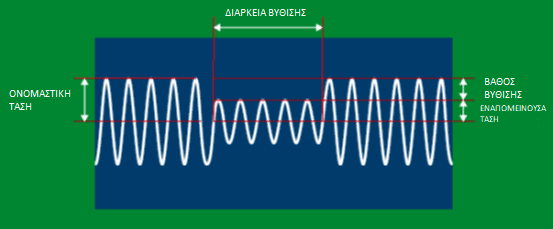

Flickering has to do with amplitude modulation (AM) of the 50 Hz voltage at smaller frequencies (0.5 – 20 Hz).

Its most common consequence, from which it has taken its name, is the flicker of the lighting of the premises.

Contrary to the overwhelming impression that it is due to old-fashioned luminaires, we can see that it still appears even in the most modern LED lighting installations,

Due to the very low frequencies mentioned above, flickering compensation can not be made simultaneously with the compensation of common harmonics of 150, 250 Hz, etc.

Therefore, the only way to deal with the flickering phenomenon is to use active filters, but they should be equipped with properly designed software.

Active EMMIS filters support the ability to dampen flickering, as all versions are fully compatible with the corresponding software.

Conclusions

As can be seen from the above, the widespread use of modern technological equipment in industry, shipping, hospitals, building facilities and RES projects is the main cause of harmonic creation and involves various problems, more or less complex, depending on the installation.

In order to be able to deal effectively with the problem of harmonics, a complete study of its installation is required – in any case – to document the source of the problem and its consequences.

In this way, a complete and clear picture is obtained with all the necessary information, so that the most appropriate equipment is then documented.

At the same time, it is ensured that the problem of harmonics is tackled at the lowest possible cost, that unnecessary and costly actions are avoided, and that the treatment is targeted and holistic.

EMMIS provides complete solutions to addressing harmonics, from measurement and study to the installation of appropriate equipment and maintenance, guaranteeing the predicted outcome, depending on the specifics of your installation.